MUTOH paint spraying digital printing solutions

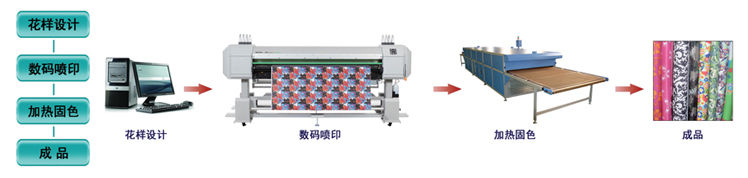

Paint direct digital printing is the simplest technology in digital printing. It can be printed directly on the fabric. The fabric can be processed without pretreatment. After printing, the fabric can only be dried and solid color.

Compared with dye ink, coating ink has the following advantages:

1. Versatility for different fibers.

Different fibers need to use different dye ink, and the paint ink applies to all kinds of fabrics.

2. Simple application process.

The coating ink is applied to fabric inkjet printing without complicated pretreatment and post-treatment process. It can be sprayed directly into the fabric, and then only simple baking can be done.

3. No sewage discharge, good for environmental protection.

After ink-jet printing, after solid color, the paint will not generate floating color on the fiber, so it does not need to be washed in the same way as dye ink to remove the floating color.

4. Good light fastness.

Paint ink jet to the fabric, exists in the state of tiny particles on the fiber, so it's not easy to light decomposition, even particles outer molecules break down by the light, as will keep the color lining. While different dye ink, ink jet to the fiber, they to dyed fiber molecular states, and most in the fiber is also exist in molecular state or relatively loose aggregation, so easy to break down by the light.

But, unlike the dye ink, paint ink is to rely on tiny coating particles on the fiber surface display color, so the paint ink color expressive force is less dye ink and general paint ink, especially domestic ink difficult to meet the requirements of customers, at present only imported paint ink can show the colorful color.

MUTOH paint spraying digital printing solutions

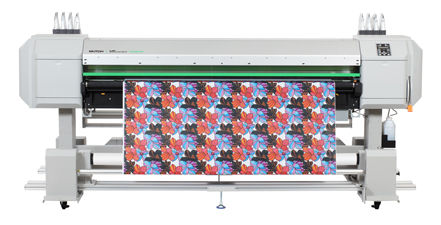

1. Recommended printing equipment: vj-1938tx

Vj-1938tx, the maximum printing width of 1,900 mm, the production speed of 50 square meters per hour;

The printer standard is equipped with the original automatic collection and release system, which can directly print the pure cotton, high-content cotton blended, polyester fiber and other fabrics. The vj-1938tx is two to three times faster than the average printing device, and an operator can watch over multiple devices, saving people and the cost of the site.

2. Ink: Japanese original factory textile paint ink

3. RIP software: Wasatch RIP software

4. Auxiliary equipment: tunnel dryer or continuous steam box

Company profile

Guangzhou super Aaron technology co., LTD. (hereinafter referred to as super Aaron) was founded in 1997, is a muto MUTOH digital printing machine in south China area general agent, China and India UV coil printer in guangdong province general agent, etc., in a professional r&d large-format printing equipment solutions...

MoreCompany news

WeChat public

Scan for more information