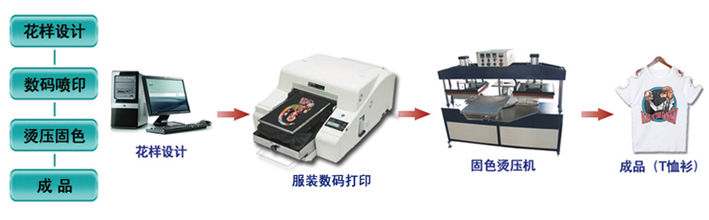

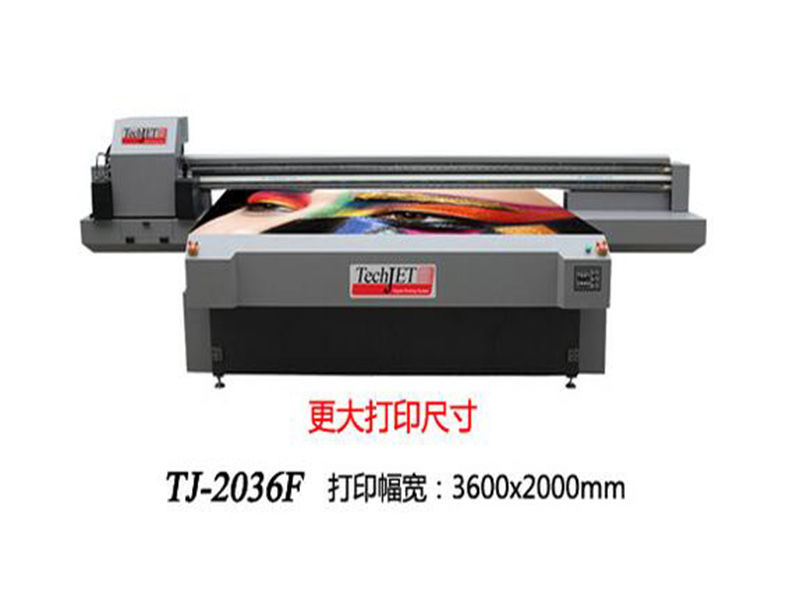

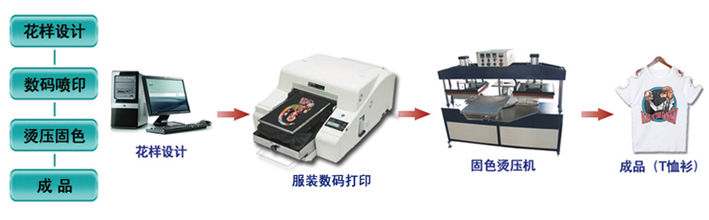

The digital printing of clothing is a kind of printing method that can be printed directly on the clothes by the tablet printer. This type of printing is based on the use of ink. There are two main techniques: One is the use of active or acidic ink printing, which is mainly for sweaters, t-shirts and other garments, suitable for wool, cashmere, cotton, blend, nylon, etc. The advantages of this type of printing are: the fabrics are widely used, the garments are brightly colored and the saturation is high. The disadvantage is that the process is complex and requires a lot of hardware equipment. The printed clothes need to be processed and steamed, washed and dried before being processed. The other is the use of textile pigment ink printing, which is mainly aimed at personalized t-shirts, which are suitable for fabrics such as pure cotton, high cotton blend, polyester fiber, etc. The advantages of this type of printing are: the process is simple, without complex pretreatment and post-treatment, the printed garment needs simply pressing and pressing; The disadvantage is: the color of domestic paint ink is poor, want to pursue high quality needs to use import textile pigment ink. MUTOH company the latest high quality clothing digital printing machine VJ - 405 gt and VJ - 405 gt, adopts industrial-grade piezoelectric print head, image printing quality, colour is gorgeous, color reduction accurately, support the white ink printing, adopt safety environmental protection textile pigment ink, easy to print all kinds of fabrics such as pure cotton, blended yarn, polyester. MUTOH garment digital printing solutions 1. Printing equipment: vj-405gt/vj-404gt 2. Ink: Japanese original factory textile pigment ink 3. Software: MUTOH Layout And PrintTool 4. Auxiliary equipment: pressing machine or tunnel dryer Curing temperature and time: press 180 ℃ / 60 seconds.

|